| Nominal storage capacity | L | 330 |

|---|---|---|

| Empty weight | kg | 220 |

| Filled weight | kg | 550 |

| Rated heat input [Qn] | kW | 49.9 |

| Rated heat output [Pn] | kW | 50.6 |

| Nitrogen oxide [NOx] | ppm | 19.7 |

| Nitrogen oxide emission [NOx] | mg/kWh | 39 |

| Noise level | dB(A) | 62.9 |

| Noise level inside [LWA] | dB | 62.9 |

| Efficiency | % | 101.5 |

| Maximum working pressure | kPa (bar) | 600 (6) |

| Energy efficiency class | A | |

| Efficiency [ηwh] | % | 101.5 |

| Load profile | XXL | |

| Annual electricity consumption [AEC] | kWh | 25 |

| Daily electricity consumption [Qelec] | kWh | 0.113 |

| Annual fuel consumption [AFC] | GJ | 21 |

| Daily fuel consumption [Qfuel] | kWh | 26.388 |

| T cold | °C | 10 |

| T storage | °C | 60 |

| Draw-off capacity continuous withdrawal [ΔT=25°C] | l/h | 1742 |

| Draw-off capacity continuous withdrawal [ΔT=50°C] | l/h | 871 |

| Recovery time [ΔT=25°C] | min | 11 |

| Recovery time [ΔT=50°C] | min | 23 |

| Draw-off capacity - single withdrawal [ΔT=25°C] | L | 660 |

| Draw-off capacity - single withdrawal [ΔT=50°C] | L | 330 |

| Power supply | V/Hz | 230 V ~ 50 Hz |

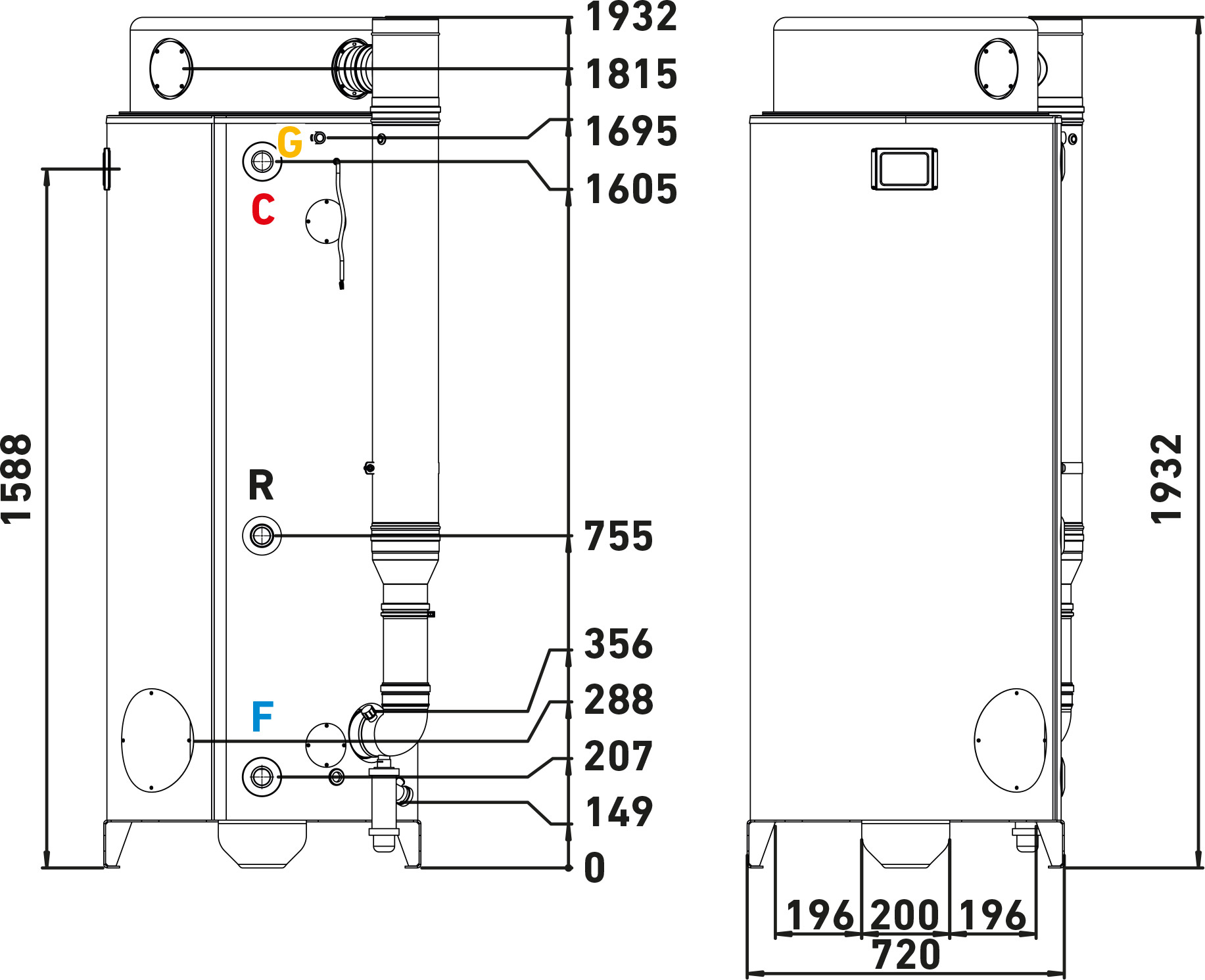

| Dimensions (w x d x h) | mm | 720x720x1932 |

| Cold Water Inlet [F] | in | G 1”¼ |

| Hot Water Outlet [C] | in | G 1”¼ |

| Gas Inlet [G] | in | G 3/4” |

| Recirculation [R] | in | G 1”¼ |

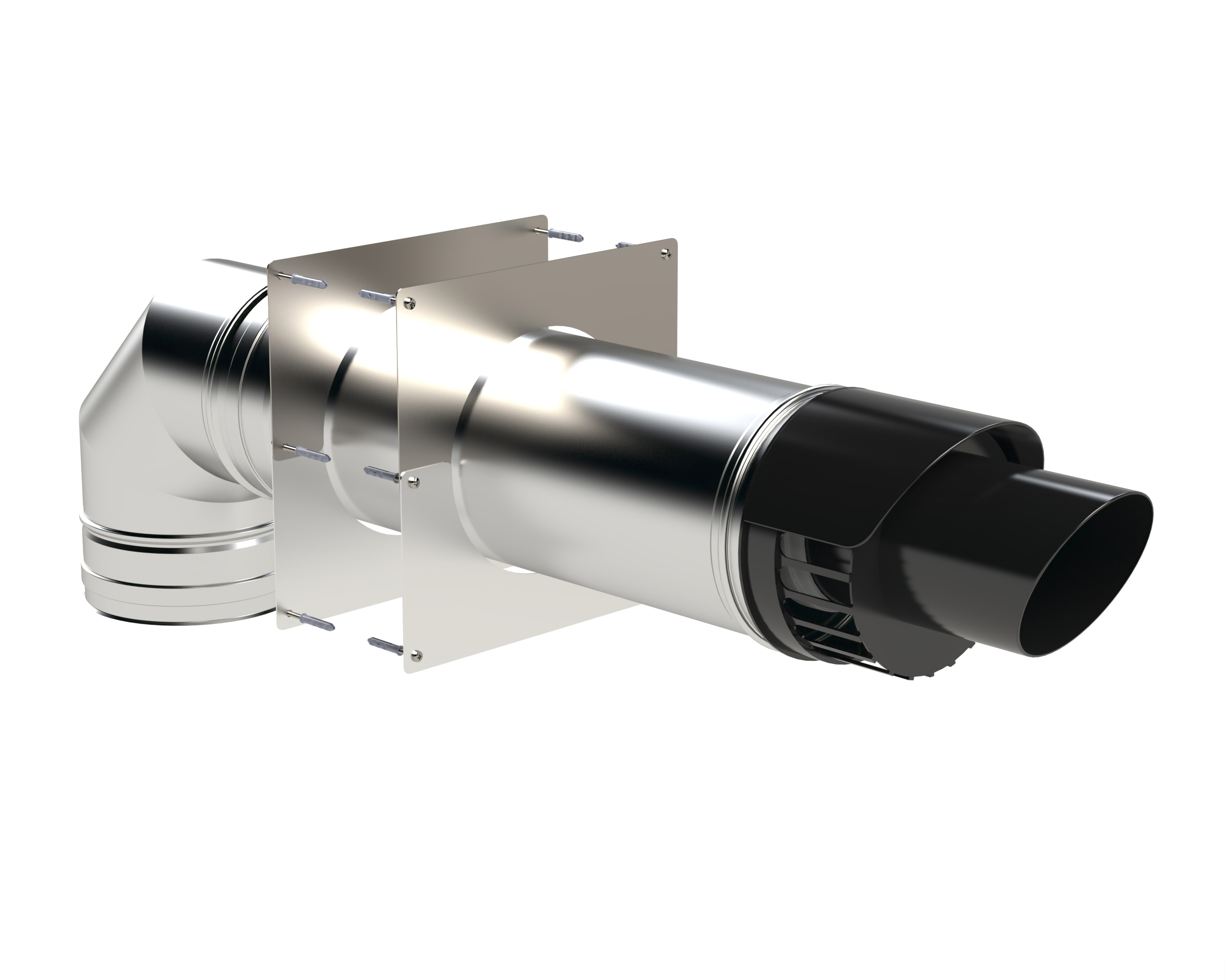

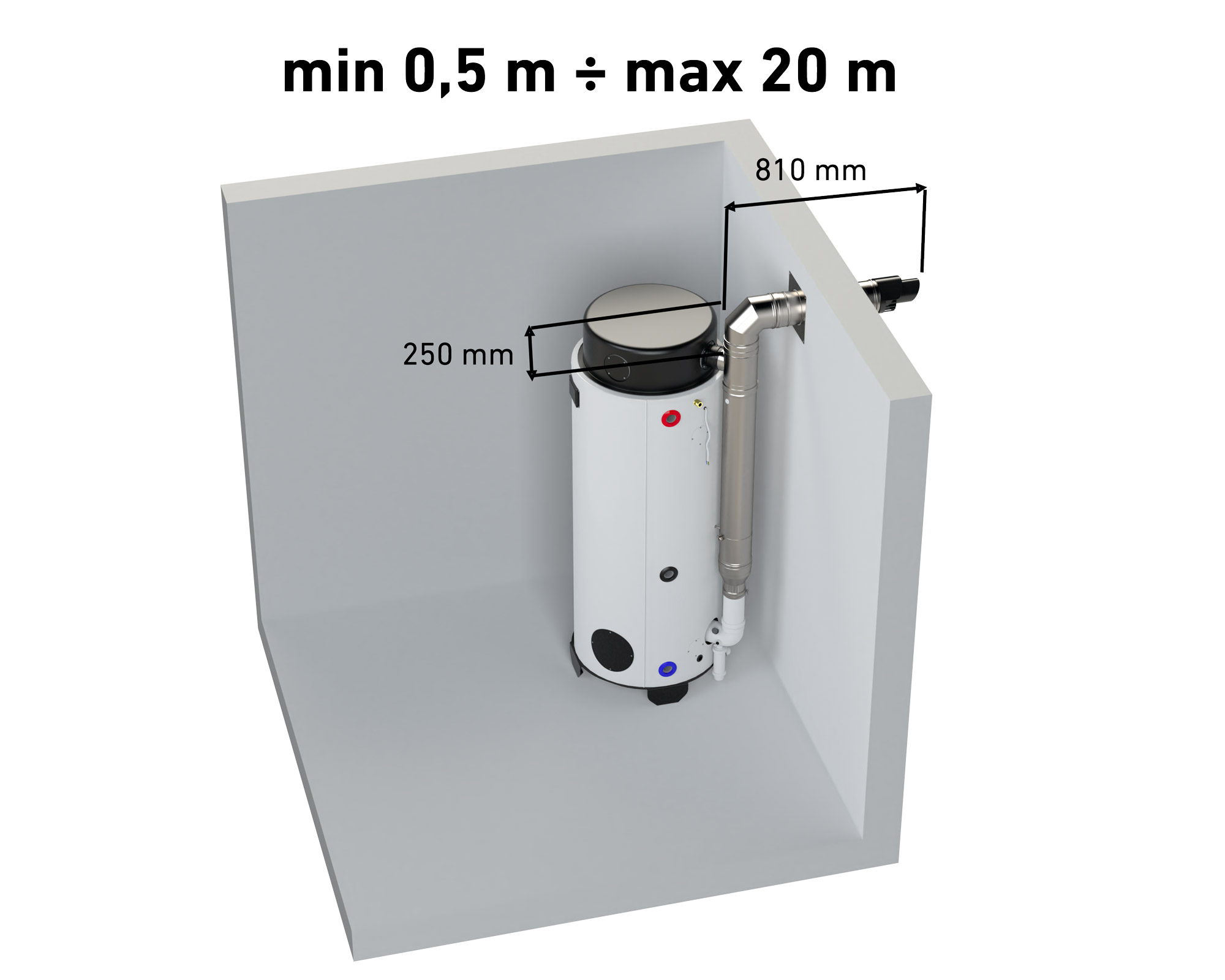

The boiler is supplied without an exhaust kit. The following table shows available kits for this appliance.

Use only the original kits supplied by the manufacturer (to be purchased separately according to the type of exhaust intended).

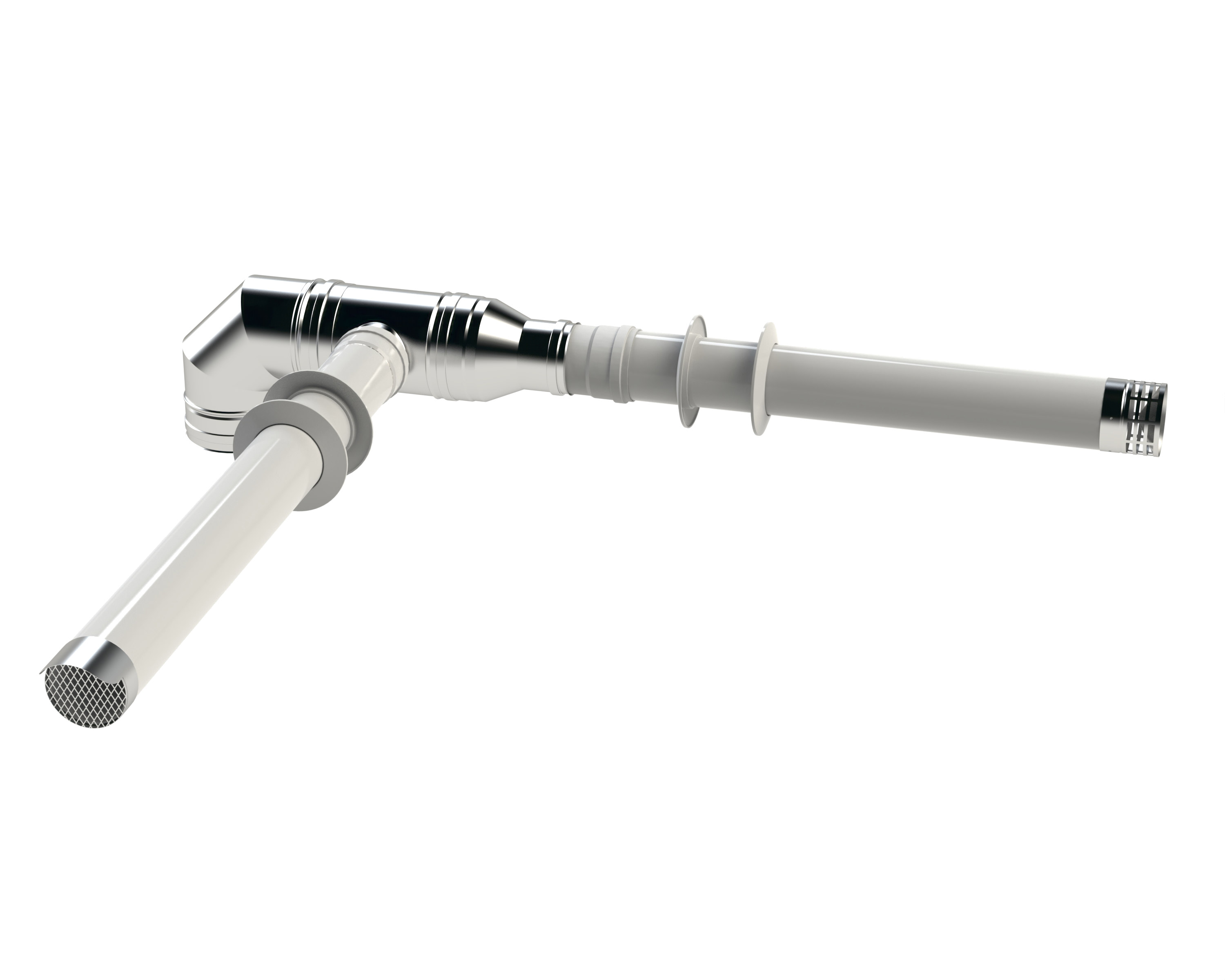

Ø100 / 150 PP-St. steel horizontal concentric flue kit

C1

Contents

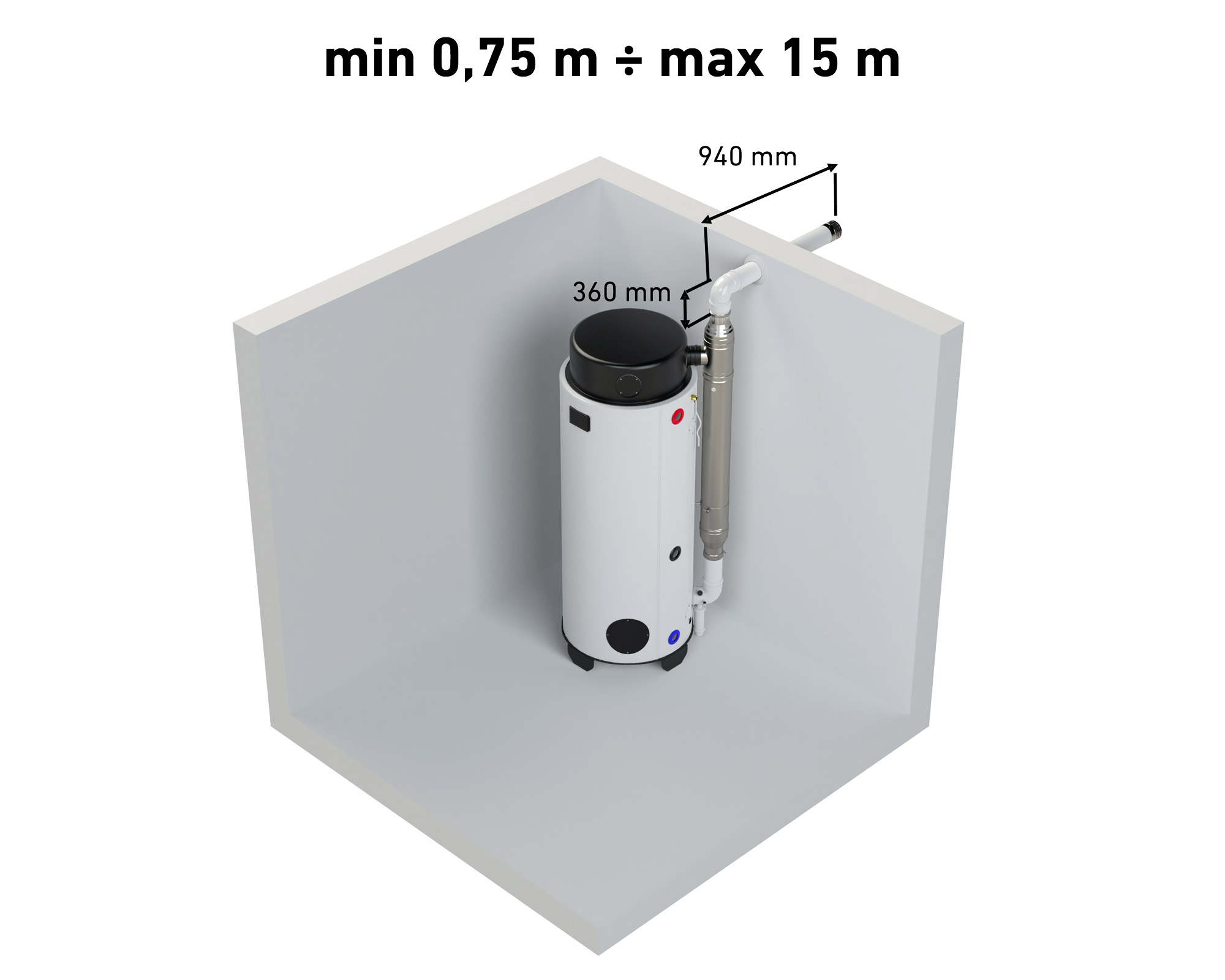

Dimensions and limits of use

Accessories and extensions

| Photo | Code | |

|---|---|---|

|

WXPX1015050 | Concentric extension PP/st. steel Ø100/150 L= 500 |

|

WXPX1015100 | Concentric extension PP/st. steel Ø100/150 L= 1000 |

|

WXPX101545 | Concentric elbow PP/st. steel Ø100/150 45° |

|

WXPX101590 | Concentric elbow PP/st. steel Ø100/150 90° |

Ø100/150 PP-St. steel vertical concentric flue kit

C3

Contents

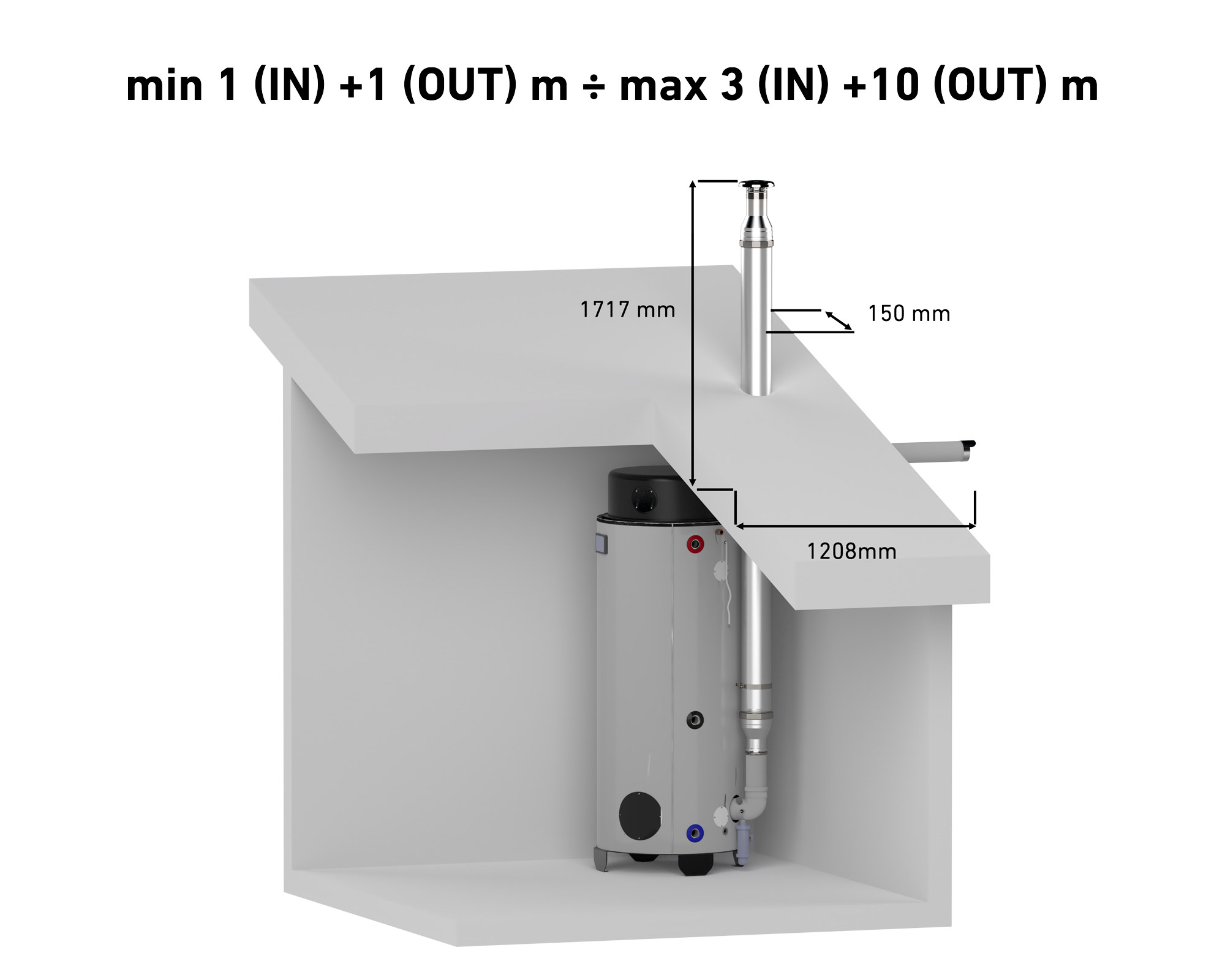

Dimensions and limits of use

Accessories and extensions

| Photo | Code | |

|---|---|---|

|

WXPX1015050 | Concentric extension PP/st. steel Ø100/150 L= 500 |

|

WXPX1015100 | Concentric extension PP/st. steel Ø100/150 L= 1000 |

|

WXPX101545 | Concentric elbow PP/st. steel Ø100/150 45° |

|

WXPX101590 | Concentric elbow PP/st. steel Ø100/150 90° |

Ø100 PP type B open chamber horizontal flue kit

B5

Contents

Dimensions and limits of use

Accessories and extensions

| Photo | Code | |

|---|---|---|

|

AKIT33-01 | PP extension Ø100 L= 500 |

|

AKIT33-02 | PP extension Ø100 L= 1000 |

|

AKIT33-03 | PP elbow Ø100 45° |

|

AKIT33-04 | PP elbow Ø100 90° |

Ø100/100 PP single wall horizontal flue kit

C4,C5,C8

Contents

Dimensions and limits of use

Accessories and extensions

| Photo | Code | |

|---|---|---|

|

AKIT33-01 | PP extension Ø100 L= 500 |

|

AKIT33-02 | PP extension Ø100 L= 1000 |

|

AKIT33-03 | PP elbow Ø100 45° |

|

AKIT33-04 | PP elbow Ø100 90° |